|

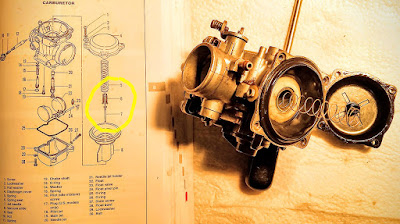

| Two decade old parts mean things don’t fit together. Making something work in this circumstance seldom has anything to do with following directions |

The other day I was trying to install carburetors on an old motorcycle (I was a millwright before I was an IT guy). I wasn’t even sure if what I was doing was possible. I spent a couple of frustrating hours trying before I pulled it all apart and did it over a different way.

What I love about technology and engineering, especially when it involves free-form building rather than following directions, is that you have no idea if what you’re doing is possible. This never happens in digital environments – they’re all designed for you to eventually succeed. Kids think video game wins are wins, they’re not, they’re a conditioned response.

Any teacher who thinks free form building is just for fun is the kind of teacher who only wants students to perform conditioned response with a predetermined outcome (I’m guessing so they can control the situation). A lot of people (students and teachers alike) think that’s learning. I think it’s all about management and control, and it’s one of the emptiest things we can do with students.

What would a learning environment look like if it wasn’t modelled on data collection and teacher insecurities?