With the snow finally falling I’ve had time to start into the naked Concours project. The first thing that needed addressing was the final drive unit which was leaking from the inner seal. When the Clymers manual says you can do it but it’s a big pain in the ass, it’s best to have a practised hand do the work. I took the unit off (easily done as it’s held on the drive shaft by four bolts) and loosened all the fasteners on the inner plate.

Two Wheel Motorsport, my local Kawasaki dealership, said they could do the work and estimated two hours of shop time and a twelve dollar seal. I dropped off the unit and got a call back four days later saying it was done. It was a nice surprise to find that the work took less than an hour and my $250 estimate was suddenly a $120 bill. You hear a lot of negative talk about dealerships but Two Wheel did this job professionally and quickly, and then didn’t overcharge when they easily could have.

I cleaned out the shaft drive end and re-greased everything. Reinstalling the unit was easy and straightforward. With the grease holding the spring in place I was able to simply slot the drive unit onto the shaft splines and re-torque the four nuts. Everything went together smoothly and the drive feels tight and positive.

Since this was the only mechanical issue with the Concours I was able to begin thinking about the customization side of things. With over 100lbs of plastic and metal removed from the bike I needed to start thinking about how to minimally dress this naked machine in order to cover up the plumbing and electrics. Having a metal shop at work means handy access to fabrication tools. Our shop teacher is also a Concours owner and is eager to help with panel building. He suggested I do cardboard cutouts of the pieces I need and then we can begin the process of creating metal body work.

| Body work craft day in the garage. |

Doing the cutouts is tricky even in cardboard. The left side cover goes over some electronics including the fuse panel and needs to bulge outward in order to contain all of that. The right side is more straightforward but still needs cutouts for the rear brake wiring and rear suspension adjuster. I’m curious to see how close the metal cutouts come to the cardboard templates.

The shop at school has a plasma cutter and we should be getting a laser engraver shortly. With such advanced tools I’m already thinking about engraving panels. Collecting together a bunch of line drawings of iconic images and sayings in a variety of languages would be an interesting way to dress up the minimal panels on this bike. If the laser engraver can work on compound shapes I might drop the gas tank in there and engrave Kawasaki down the spine of it where the gold stripe will go rather than looking for badges or decals.

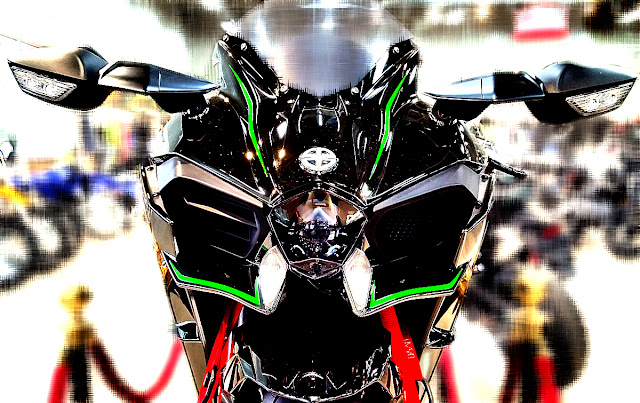

I enjoy the mechanical work but now that the Concours is working to spec I can focus on the arts and crafts side of customization. Next up is trying to figure out how a minimal front panel that contains the headlight and covers up the electrical and plumbing at the front will look.

via Blogger http://ift.tt/2fFw0bS