|

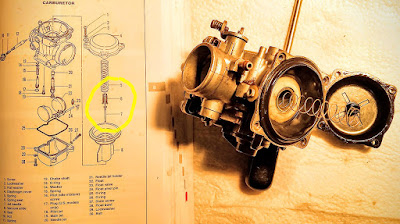

| A 2007 Ninja 650R with its pants down (chain and front sprocket cover removed) |

If you’ve never done chains and sprockets on a motorcycle before, there is more to them than what you’ve done with a bicycle chain. Being an open part of the drive system, they offer a relatively easy way to modify your bike’s performance. With smaller (faster) sprockets you can produce a revvier, shorter geared engine. With a shorter chain you can close up your wheel-base creating a bike more willing to change direction. Chains and sprockets are a bike fettler’s delight.

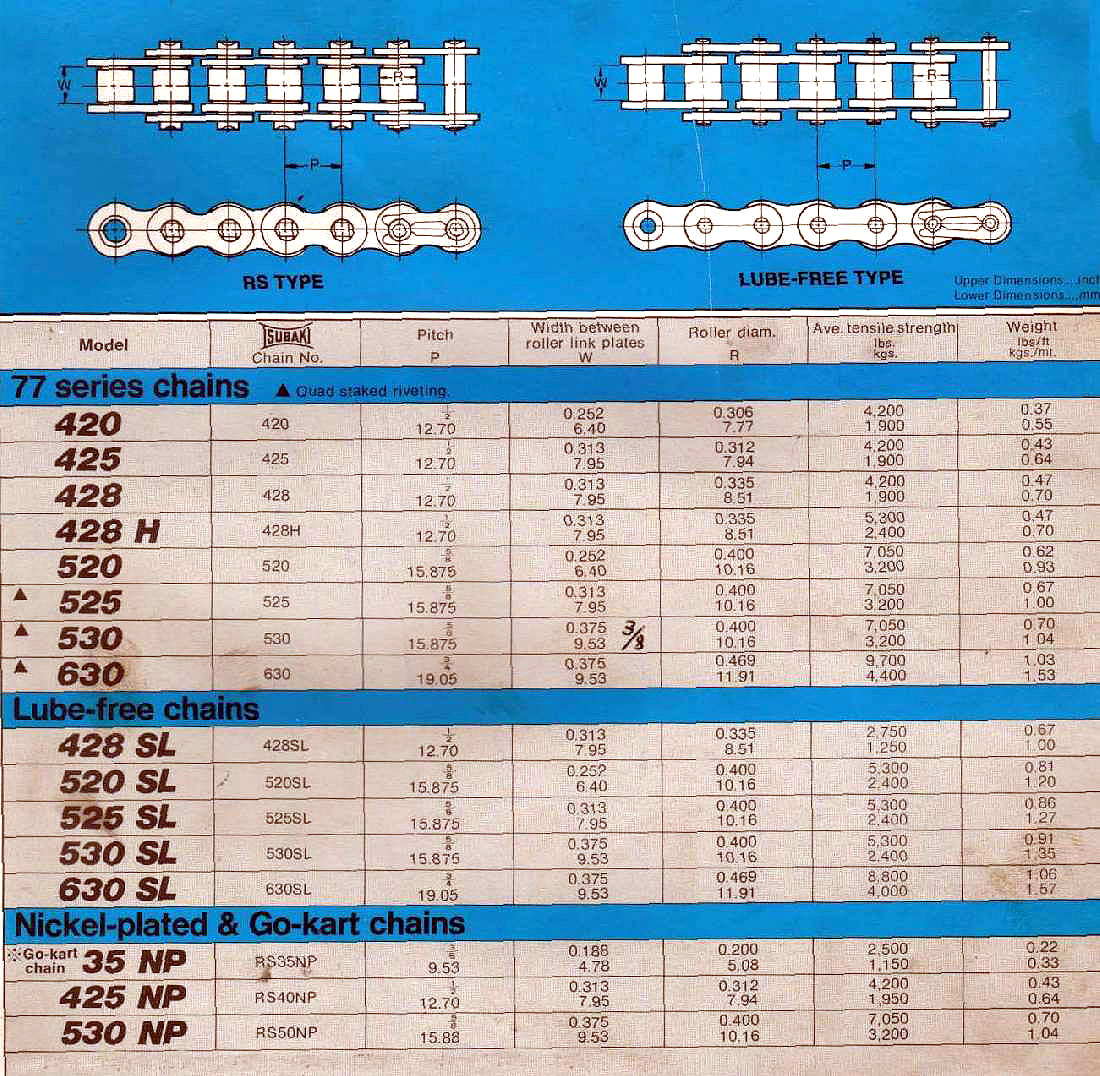

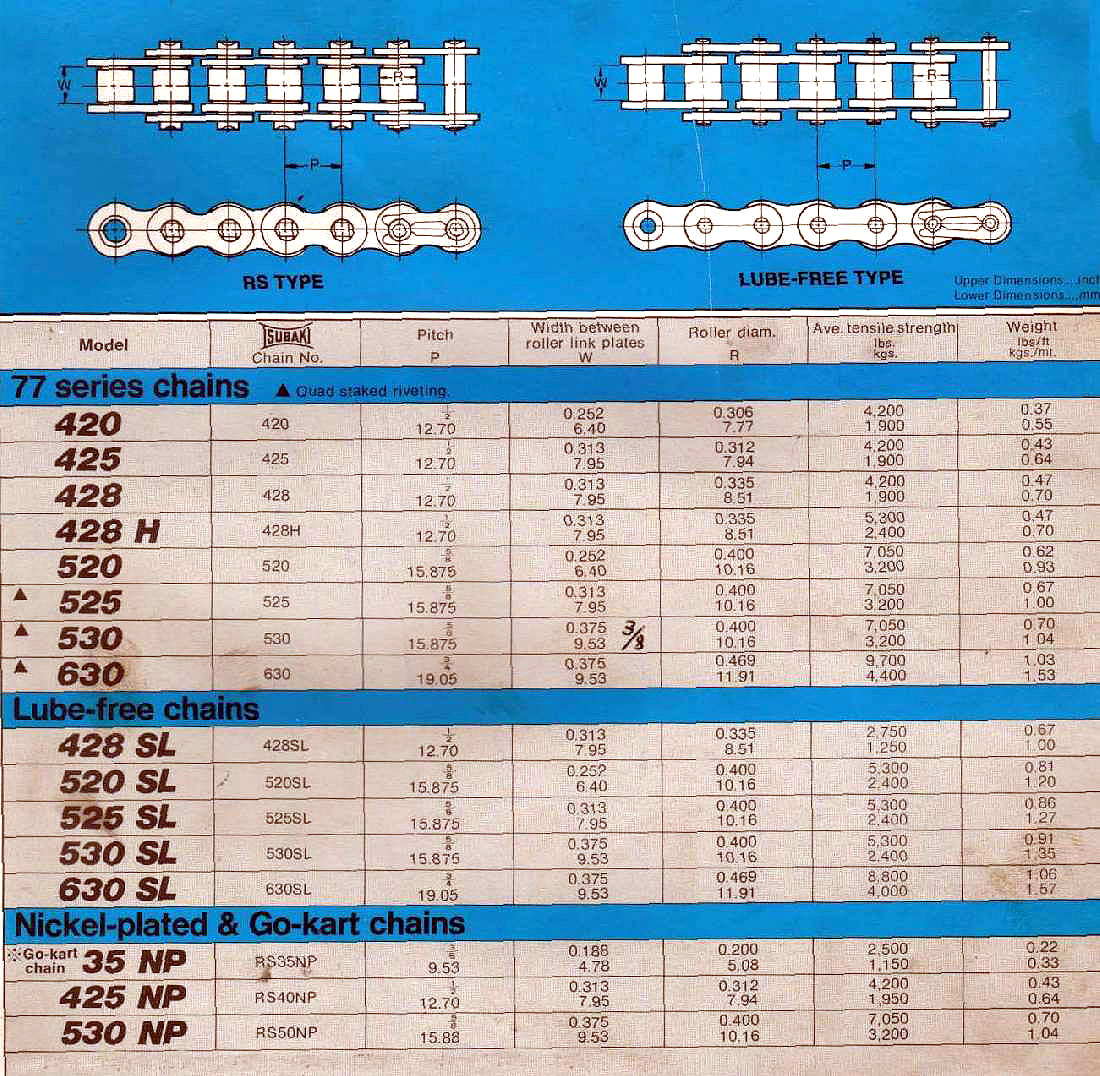

On top of sprockets, you also have a pile of chain choices. O-ring chains are the cheaper, lower efficiency alternative, while X-ring chains offer more efficiency and less maintenance at a higher cost. They also come in a rainbow of colours and a variety of sizes from little dirt bikes all the way up to thousand plus cc super-bikes.

|

| Chain sizes and dimensions |

|

| From little dirt bikes to bike motors. |

Chain sizing is based on the width of the chain and the length between the pins in the chain. You’ve got match all these up with the right sprockets or it won’t all fit together. With so many factors in play, it pays to get a handle on chain mechanics before you take a run at changing the chain on your motorbike.

Here’s a primer on how to break a chain. Some people say cutting a chain but you aren’t cutting it, you’re breaking it by popping the rivet out and dismantling the chain links.

How to Break a Chain:

- If you’re removing your old bike chain, find the master link (it should be the one that’s different from all the rest)

- Put a chain breaking tool on the chain and push the rivets out – do a bit on each side at a time until the chain ‘breaks’ open. I did this with a bicycle chain breaker (see bottom) and it worked fine.

- Once you’ve ‘broken’ apart the master link the chain will come apart and you can pull it through and free of the bike.

To reduce chain size on a motorcycle:

- if you have a 520 or smaller chain and a good motorcycle specific chain link breaking tool you can simply push the rivet through (see the video at the bottom)

- if you don’t have specific tools, grind or file down the rivet and then tap it out with a hammer and punch pin. If you grind down the rivet you can also use a bicycle weight chain breaker (see a pic at the bottom) to push out the worn down rivet.

- triple check which link you want to pull and use something like Gearing Commander to make sure you’ve got the right number of links in your chain. (This is what I’m kicking myself for not doing).

- Using the bicycle chain puller on filed down pins, I pushed on side and then the other and then repeated the process and the rivet popped loose along with the outer chain links. Since you’re only filing down the outer link (which you’ll chuck after) it doesn’t matter if you file into it a bit.

- With the chain dismantled you should now have two inner links ready for a new master link.

Installing a New Master Link:

- Install the little rubber washers on the master link rivets and slide it onto the chain – do this on the sprockets as it’s easier to do with some tension on the chain.

- put the last two rubber washers on and the end plate and then use the chain tool or some other kind of clamp to press the side plate on.

- if you’ve got a rivet type master link you need a light hand and some patience to press in the rivet ends. If you’re too heavy handed you’ll bind the chain and swear a lot.

- The more traditional type of master link is the kind I was familiar with from bicycles. It comes with a slid on clip.

Don’t freak out if you’ve got the rivet type master link, just make sure you have the right tool handy. The rivet type link is very strong and performs pretty much like all the other links if installed properly, which is why you’ll find it exclusively on high performance chains. Check out the youtube video at the bottom for a good primer on how to do this.

If you take your time and work through it slowly, you’ll have a new chain on in no time. If you want to get into sprockets the rears are remarkably easy to do. When you remove the rear wheel bolt the wheel drops down and the floating rear caliper on the Ninja 650r simply disengaged and I hung it on the frame. You can then remove the wheel. The rear sprocket is held on with your typical nuts and was easy to swap out.

|

| This front sprocket is a f&#*er. |

The front sprocket was in good shape, so I gave up on it. Others online have said that they are pretty straightforward if you have an air gun, but even with a breaker bar I couldn’t budge the damn thing and I can pick up a car by the fender. You remove the front sprocket by bending back the holding washer, putting the bike in gear, stepping on the rear break to hold everything still and removing the nut (it’s a good fit on a big 27mm bit). If there’s a trick to this (other than getting a compressor, air tank and air tools), I’d love to hear it.

Follow up with Chain And No Agony for how easily the new chain went on with the right tools.

|

If you’ve only got a bicycle chain

breaker, file or grind down the rivets

first before you push them out. |

If you’ve broken bicycle chains before you know the basics. Motorcycle chains are much heavier duty so the process requires stronger tools capable of dealing with stronger rivets. If you have a bicycle chain breaker you just have to take your time and file down the rivet you’re going to push through first. It took me a couple of minutes of filing to do this. Lazy people on the internet say buy a Dremel. If you’re lazy, that’s what you should do.

VIDEOS

A video on how to break a motorcycle chain (skip to 35sec when the mechanic comes in) in order to re-size it using a motorbike specific tool

A good primer on how to install a master link (and how the pressed, rivet type master links work)

How to measure a motorcycle chain

Hillbilly mechanics: how to do a master link without special tools.

LINKS

Gearing Commander – a handy webpage that lets you compare different sprocket and chain combinations

http://www.gearingcommander.com/

DID company chain guide:

http://www.didchain.com/chainSpecs.html

Motorcycle Chain primer on about.com

http://motorcycles.about.com/od/motorcyclemaintenanc1/ss/Chain_Maint.htm

Wikipedia‘s history and technically detailed chain description

http://en.wikipedia.org/wiki/Roller_chain

.png) |

| Layout of a roller chain: 1. Outer plate, 2. Inner plate, 3. Pin, 4. Bushing, 5. Roller |

An exhaustive history of chains!

How Motorcycles Work‘s awesome chain diagram:

.png)