from Blogger https://ift.tt/2QpBoj1

via IFTTT

Tim King's homepage with images and writing about technology, education, visual art and motorcycles!

from Blogger https://ift.tt/2QpBoj1

via IFTTT

|

| Owning a Fireblade checked a box, taught me many things and was a zero cost experience! |

I always try to balance out bike projects so that I land in the black on them. I’ve gotten pretty

good at this. The Fireblade Project cost me about $2300 all in and then I got to ride it for a season before selling it for $2500, which I then put towards the Concours14. Even with fancy seats, windshields and other gubbins, the Connie only owes me about $7000. Older model, double the mileage bikes are going for eight grand, so I’m still ahead there too.

People who throw big money down on customization that they like seem to think other people will pay extra to adopt their choices and tastes, which never made a lot of sense to me. This goes for houses or in vehicles – just because you’re willing to pay a premium to get a certain look, doesn’t mean anyone else is, and expecting them to shell out for your choices is a bit naive.

|

| The Concours was a cagey purchase that still has me well in the black. |

What does always sell is functionality. As much as I’d like to get all romantic and throw money at the old Triumph I’m restoring, I’m more interested in making it work, and then riding it. To that end, I’m not interested in creating a perfect replica of a 1971 Triumph Bonneville to put in shows, so modern touches (especially when they’re more cost effective than stock-at-all-cost options) are something I have no trouble with. A bike that starts easily and runs sweetly sells itself much more quickly than a cantankerous but period correct trailer queen. One’s a motorcycle, the other is art, and art is notoriously in the eye of the beholder.

One of the reasons I’ve always gravitated toward cheap and cheerful 80s and 90s Japanese restos was because the parts are usually easy to find, including hard parts from a breaker if needed, and they’re as cheap as chips to buy because people tended to use them rather than put them up on a pedestal.

My first brush with ‘vintage’ (I think a 51 year old air-cooled Triumph from before the collapse of the British bike industry qualifies as vintage) has me wondering if my approach still works. The cost of parts is much higher than more recent Japanese bikes and this particular Bonneville was half taken apart by a muppet who wanted to be in Easy Rider, so I’m constantly finding parts missing or incorrect. I’m also struggling with missing non-metric tools after having owned metric bikes my entire life.

When I’m reading Practical Sportbikes I enjoy the articles on DIY and the stories of scratchers who got a machine put together with their own hands. When they run one of the ‘specials’ articles where it’s a rich guy with clean hands throwing money at a project, I lose interest quickly. Classic Bike Magazine is similar. When they’re talking about an owner keeping an old machine running on ingenuity and guile, I’m all in, but the minute it’s a millionaire adding to his collection with another bespoke machine put together by someone else, I’ve lost interest.

I just finished Guy Martin’s new book, Dead Men Don’t Tell Tales, and Guy ends the latest one

talking about trying to find what makes him happy. This requires a fair bit of self awareness – something that most people don’t have. Guy’s particularly difficult in that he will often act on an urge that turns out to be incorrect, but, as he says in the book, he’s evolving.

There’s a scene in Guy’s Garage where Cammy, his professional race mechanic mate, knows how to fix the car they’re working on but Guy has his own ideas and keeps bashing away at it wrong. Rather than push the point, Cammy backs off and waits for Guy to realize he’s using the wrong tool for the job.

Guy is critical of Cammy for being slack in his approach to work in the book, but I’m left wondering if the truth isn’t somewhere in between: what looks like a lack of effort from Guy’s point of view is actually a better use of his energy from the professional race mechanic’s point of view. There’s more to all this than just jumping in to the physical labour, you need to be exercising the grey matter too.

What I’m taking from this latest round of Guy Martin media is that you’re more likely to stay engaged with and finish big projects if they make sense to you. To that end, I spent yesterday working out why the kickstarter on the Bonneville wasn’t working (the muppet had put it in backwards).

The goal is still to have gone through the whole bike and have it back in working order without breaking the bank. The amount spent on it matters less than whether or not the project is in the black. If a functional ’71 Bonneville is worth about five grand, then that’s what I’ll work to on the budget, while keeping an eye on what engages me most about all this: putting a sidelined bike back into service again… and then riding it!

This morning I’m looking at Motogadget’s mo.Unit Blue and considering how to best tackle a 51 year old wiring loom that looks to be in good shape but should probably get rebuilt if dependability is the goal. An ignition powered by bluetooth on a smartphone is just the kind of steampunk anachronism that a riding focused buyer would dig. That it’s also invisible means it won’t hurt the look of the bike (the only change is the ignition key isn’t there).

from Blogger https://ift.tt/3rnOlxD

via IFTTT

I’m busy in the garage these days with the on-going 50 year old Triumph Bonneville restoration project. It’s a big project that will take some time to sort out, but it’s -20°C outside with snow squall warnings of 20cm of snow coming, which means it’s also regular maintenance time on the two running bikes in the stable.

|

| Tiger’s back in hibernation after last week’s sprockets & chain maintenance, waiting for a break in another never-ending winter of COVID for a chance to ride. |

As you would expect from Kawasaki Heavy Industries, the brakes on the GTR1400/C14 Concours are superbly engineered Nissin calipers. I’d picked up the pads last summer but they hung on the wall until now because I was putting miles on the thing. I did find the brakes were squeaking a bit, suggesting the calipers weren’t releasing properly – something that can happen in a bike that sits for several seasons. Like I said before, I don’t like riding a bike where I’m not sure of the maintenance, especially on brakes, so it was due.

Doing the pads on the Concours is remarkably easy. You don’t need to remove any body panels and everything is very accessible. Undo the pin that holds the pads and spring that holds them in and then everything comes apart in your hands. The pins were rough and there was some odd gunk stuck in the front right caliper. I cleaned everything up and lubed it and then slotted the new pads into place with the now lubed pins (I think it’s a #5 hex head that does the trick). All very logical.

|

| If you’re looking for torque settings for the brakes on a Kawasaki GTR1400/Concours C14, here they are. |

The rears are just as easy and a similar design with the same pin and caliper bolt sizes (everything is hex metric). The back was as mucky as the front and I went to lengths to clean up the pressurized caliper slider and lube the pins and areas where the pads move. The action immediately felt better afterwards.

Getting all the air out of the hydraulic clutch so that it felt tight and had positive action was a real pain in the ass last spring. The good new is that this air-line powered vacuum system did the trick then (it’s not crazy expensive) and takes the headache out of bleeding anything with steady, controllable suction.

from Blogger https://ift.tt/3FapNgG

via IFTTT

Through work I’ve done a fair bit of 3d modelling and imaging. A cheap and easy to use 3d scanner is the Structure Sensor, a laser scanner that clips on to an ipad and quickly builds a 3d model by painting it with a distance sensing laser. It takes the distances and builds up a model of polygons from the location data.

Using that process I’ve rendered 3d models as well as 2d images of them. I use Sketchfab to upload 3d models to the web to share them. 2d images are typically screen captures of the 3d models either off the ipad after the Structure Sensor scan or out of Sketchfab after they’ve been uploaded.

Here are some examples:

| This is a 3d print of the Tigertester model above. |

| These black and white images are off the Structure Sensor software on the ipad (in xray mode). |

| You can skin the image to give it colour, this is an example of the skin that would go over the wire frame model to render it in full colour. |

LINKS:

3d modelling & graphic design work on motorcycles.

3d modelling & graphic design in the classroom.

from Blogger http://ift.tt/2C88RHF

via IFTTT

This popped up on my Facebook feed. I actually contacted the local dealer about this one last year and asked if he’d consider $6500 – he couldn’t be bothered to email me back even to barter; love that arrogance.

This is a first gen Concours C14 with almost 60,000 kms on it. I ended up picking up a second gen C14 that was two years newer with half the kilometers on it for $5500. I had to put a bit of time in on it sorting out the electric windscreen, a clutch gasket and picking it up and safetying it. $5500 for the bike, $120 for the rental van to get it, $20 in parts (from Two Wheel!) and $90 to get it safetied with a $715 tax bill still had it all costing me less than $6500 on the road. Thanks to that price they’ll be looking at over $300 more just in taxes for the lucky new owner.

Even with my fancy German windshield and American saddle I’m still coming out ahead. Prefer the colour on mine too.

from Blogger https://ift.tt/3f39sQl

via IFTTT

I’ve done chains before but not sprockets. It’s a fairly straightforward bit of work you can do yourself in your shed/garage. In this case I’m doing both sprockets and chain on my 2003 Triumph Tiger 955i which has over 80k on it.

With the bike on its centre stand I removed the rear tire.

I picked up a chain breaking and installation tool a couple of years ago and it has more than paid for itself. It has pin sets that push chain pins out to break the chain (it keeps all the hardware in the handle so for the two+ years I don’t use it I’m not losing parts).

The new vs. the old front sprocket. The new one is 19 teeth, the old one 18.

The new front sprocket on the motor. These are the parts I used:

Not bad for the original stock rear wheel with over 80k on it, eh? If you think modern Triumphs aren’t well put together, this one was, and with quality parts.

The new chain and sprockets on.

The connecting link (see it?) is pressed into place with the DRC chain tool which also pushes links together as well as pulling them apart..

|

| The Tiger had a deep maintenance last year, so this year it only needed the chain & sprockets. It’s back under the blanket waiting for a break in the snow for a cheeky early-spring ride. Next up is doing the brakes on the Kawasaki, then I’m into rebuilding the Amal carbs on the 50 year old Bonneville winter project. |

If you’re looking for torque settings and parts details for a 2003 Triumph Tiger 955i while doing a sprocket and chain, here they are:

from Blogger https://ift.tt/3EK0p0R

via IFTTT

The old Bonnie has an intact loom and many of the original electrical components, but many of these pieces won’t have weathered the decades well and I’d be crazy to try and rebuild a hacked on electrical system in a fifty year old bike, so it’s all coming out. I’m going to take a page from the custom scene and build a loom from scratch and design and build a complete electrical system from scratch.

This ain’t no modern digital machine so the electrical system in it is prehistorically simple. Building a dependable replacement with quality modern upgrades (proper copper wiring, modern connectors, new electronic ignition and coils, etc). The result should be a 1971 Bonneville that is more spritely and dependable than anything that rolled off the line in Meriden in 1971.

Tutorials on creating a motorcycle wiring harness/loom:

BikeExif Tutorial: https://www.bikeexif.com/motorcycle-wiring

Rewiring tutorial: https://www.liveabout.com/making-a-motorcycle-wiring-harness-743591

Tutorial: https://purposebuiltmoto.com/motorcycle-electrics-101-re-wiring-your-cafe-racer/

Tutorial: https://www.hagerty.com/media/maintenance-and-tech/building-wiring-harness-from-schematic-to-bundle/

Resource (costs 20 pounds): https://rupesrewires.com/build-your-own-wiring-loom-pdf-book/

Another good resource ($40): https://www.amazon.ca/gp/product/0760345368/ref=ppx_yo_dt_b_asin_title_o06_s00?ie=UTF8&psc=1

I’ve purchased and read that last one – it’s a gentle introduction to electrical work but I found it a bit simple and wished it had picked up speed as it went. If you’ve never done any electrical work then it’s a good place to start, but that’s what I do all day so I was hoping for something with a bit more depth.

Replacement harness:

http://www.britishwiring.com/MC-28-PP-p/mc28pp.htm

Prebuilt ’71 Bonneville wiring harness: https://www.thebonnevilleshop.com/product/lucas-71-72-triumph-bsa-650-twins-main-cloth-wiring-harness-pn-54959629-g-99-1222-g/

The Motogadget is an all-in-one electrical block for all electrical items on a bike – it also provides you with a bluetooth connection so you could start and stop it by your smartphone:

Not really what I’m looking for for the Bonnie project, though I’ll keep it in mind for a future ground up custom build.

A new ignition barrel with keys looks to be about $80. I’ll see if Britcycle has them.

|

| The existing wiring looks like it was taken apart and left that way – I’m tempted to take it all out and just rewire it rather than trust the old mess. |

Electrical Systems Parts List:

Motorcycle wiring how to: https://docs.google.com/document/d/1zm67VyrQTS1_H7WRunfkhOZ1H6wivD6RuK6194P3lvs/edit?usp=sharing A commonly found writeup someone has done to walk any interested DIYer in how to rewire your bike.

from Blogger https://ift.tt/3FIQdai

via IFTTT

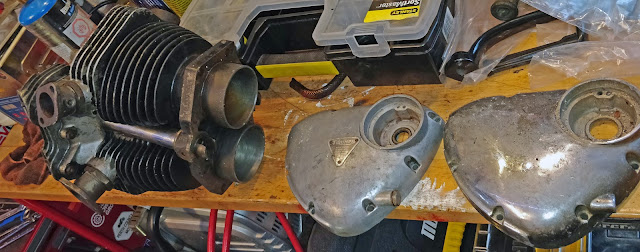

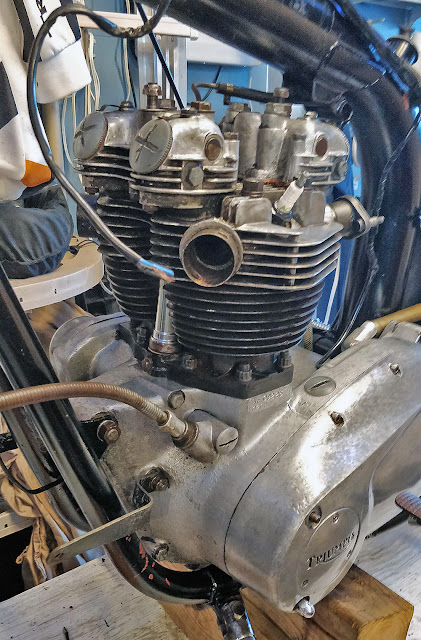

Some photos from the ongoing 1971 Triumph Bonneville winter project:

|

| One of the boxes of spares. |

|

| Spare cylinder head and engine covers. |

|

| Looking into the top of the valves… |

|

| Yep, that’s a 1984 plate sticker on it! |

|

| Front wheels cleaned up nicely. |

|

| Motor cleaned up well too! |

|

| Got it out into the minus ten sun to give it another clean up now that it’s stripped. |

|

| Strance is back to stock now that the massive chopper front shocks are gone. |

The goal is to get it mechanically sorted and ride it rat-bike style next summer to iron out an kinks. Next winter it’ll all come apart again and this time the frame will get painted and so will the body panels. I’ve found some year correct Triumph badges but I’m thinking something a bit non-stock for the paint job, like perhaps a Gulf racing livery colour scheme:

I’m also thinking about seats. A plain stock seat costs the better part of $500US. For only $100 more I could get a custom coloured Corbin seat!

https://www.corbin.com/triumph/vintlist.shtml

More research needed, but that looks sharp! You can customize Corbin vintage seats like their modern bike seats, so I could match it to the Gulf racing colour scheme too.

from Blogger https://ift.tt/3qAxB5W

via IFTTT

Sometimes the on-bike cameras in MotoGP capture a magic moment. In this case it’s Sam Lowes knocking out a fastest lap in free practice before qualifying at the Doha GP in the spring of 2021.

|

| Sam Lowes putting in a fastest lap at the Doha GP in the spring of 2021 |

from Blogger https://ift.tt/3mhKAIt

via IFTTT

Taken between 9-10pm on March 17th using the Canon T6i – ISOs from 6400 and up, F stops from 5-11, 30 second shutter…

from Blogger http://ift.tt/2u7WHz2

via IFTTT